Huadong Cable Group is a professional 3 core armoured cable manufacturer. Please kindly send us your inquiry 3 core armoured cable size and order quantity. Our sales team will send you 50mm 3C armoured power cable price and specification to you.

How to produce high quality 3 core armoured cable?

The basic process of 3 core armoured cable manufacturing process has eight steps. For example, when we produce 3C 185mm armoured cable, the first step of 3 core armored cable is copper, aluminum single-wire drawing. In this item, we choose superior copper and aluminum rods as 3 phase armoured cable material. Increase the length and enhance the strength of a drawing machine through one or more die holes of the drawing die. Drawing wire is the first working procedure of each 185sq mm 3 core armored cable company. The main process parameter of wire drawing is die matching technology. If you need 3 core armored cable, huadong Cable Group is definitely your ideal choice.

Voltage: 0.6/1kv, 3.6/6kv, 6/10kv, 8.7/15kv, 12/20kv, 18/30kv,21/35kv

Armoured: SWA (Steel Wire Armoured) / STA(Steel Tape Armoured)

Insulation: XLPE / PVC / LSF / Fire Resistant

Section Area: 1.5mm2-800mm2

Standard: IEC 60502, BS 7870, GB/ T12706 or other.

Application: Building, Engineered, Railway, Plant Construction, School, Hospital, Underground and so on.

The second step of 3 core armoured cable is single wire annealing. Copper and aluminum monofilament can improve the toughness and decrease the strength of single wire by recrystallization at a certain temperature. So as to meet the requirements of three core armoured cable for conducting wire core. The key of annealing process is to prevent the oxidation of copper wire. As a professional 3 phase armoured cable manufacturer, you can rest assured to buy Huadong Cable Group’s 3 core armored cable products.

3 phase armoured cable stranded conductor

The third step of 3 phase armoured cable is stranded conductor. In order to improve the flexibility of three phase armoured cable for easy installation. The conductive core to take a plurality of monofilament twisted together. From the form of 3 core armored cable core, we divide it into regular and irregular twisting. When you buy 3C 240sq mm cable, you can find their type ares are not the same. Anyway, whatever twist way do you need, just leave your specific requirements, we will manufacture it for you.

Conductor: Aluminum / Copper

Size: 16mm, 25mm, 35mm, 50mm, 70mm, 95mm, 120mm, 150mm, 185mm, 240mm, 300mm, 400mm and so on

Insulation: XLPE (Cross-linked Polyethylene)/PVC(Polyvinyl-Chloride)

Amoure: STA(Steel Tape Armoured)/SWA(Steel Wire Armoured)

Screen: Copper Tape screen

Sheath: PVC (Polyvinyl Chloride)/PE(Polyethylene)

In order to reduce the occupied area of the armored cable 3 core conductor and reduce the geometric size of the 3 core armoured cable. The twisted form is adopted at the same time of the twisted conductor. So that the ordinary circle can be changed into a semicircle, a sector, a tile shape and a compacted circle. Armored cable 3 core power cable mainly use this kind of conductor. Don’t worry if you have some problems on the three core armoured cable. Please contact us and Huadong Cable Group will give you some professional solutions to solve your problems.

3 core armoured cable insulation extrusion

The fourth step of three core armoured cable is insulation extrusion. 3 core armored cable are mainly extruded solid type insulation. There are three main technical requirements of plastic insulation extrusion. Eccentricity, and smoothness, density. The deviation value of extrusion insulation thickness is an important symbol of the extrusion process level. Most of the 3 phase 10mm armoured cable product structure dimensions and deviation values are clearly stipulated in the standard. Extruded insulation surface requirements smooth, not rough surface, coke, impurity poor quality problems. The cross section of extruded insulation layer should be compact and strong, no pinholes visible to the naked eye, and no bubbles. If you need to learn more about 3 core armoured cable insulation, please contact us any time.

3 core armored cable information

The fifth step of 3 core armoured cable is cable formation. In order to ensure the forming degree and reduce the shape of this kind of underground armored cable, we usually twist the 3 core armoured cable in a circular way. The mechanism of the twisted 3 core armoured cable is similar to that of the conductor. Huadong Cable Group has advanced production technology and professional technical staff. Each production step has professional inspectors to monitor the quality of the 3 phase armoured cable.

The technical requirements of 3 phase armoured cable forming are as follows. One is to prevent the abnormal insulated wire core from turning over. The other is to prevent the insulation layer from being scratched. Most 3 core armoured cable are completed in the other two processes at the same time of 3 core armored cable laying. One is filling, ensuring the three phase copper armoured cable is round and stable. The other is binding to ensure that the 3 core armoured cable core is not loose. Huadong Cable Group manufactures all types of 3 core armoured cable. No matter what type of 3 core armoured mains cable you need, Huadong Group can make it for you.

Three core armoured cable protecting layer

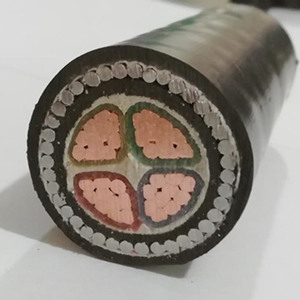

Three core armoured cable protecting layer include inner covering, armoured layer and over sheath. The inner sheath is to protect the insulated core from being damaged by armoured material. Armoured layer is to protect the armored cable 3 core cable from mechanical damage. The outer sheath is the structural part that protects the insulation layer of the 3 core armored cable against the erosion of environmental factors.

Huadong Cable Group produce 3 phase armoured cable according to the standard strictly. Meanwhile, we provide custom service. Huadong Group can customize the 3 core armored cable according to your requirements and cable usage environment. What are you waiting for? Just leave your message. Then, let’s start a pleasant cooperation with us now.